Supercharger Porting - What Everyone Misses

Before the Port...

I have a lot of customers ask me, "why do I need bearings, or new parts in general when we do our supercharger porting work?" The answer is simple.

If we break down a bearing, we are talking about a center that rotates around an outside set of round balls and that in turn rotates around a larger circumference of a frame. That's a bearing. The center moves, the outside does not - hopefully.

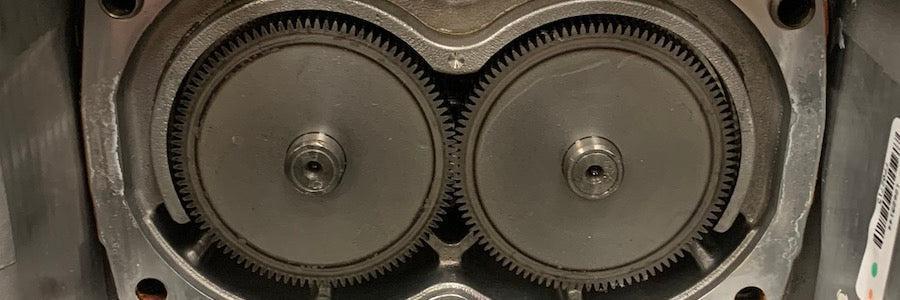

So we have these pairs of rotors and they have two bearings in the blower case for each rotor. Each one of those bearings has its specific job, specifically to keep the rotor center and let it spin freely. It sounds really easy if you ask me but when you actually see that the bearing itself it's a plastic cage that houses the needles for the bearings and it may shock you. So here we are - a single bearing asked to spin very fast. Let's do the math.

Twisting the Rotors

To calculate a pulley ratio you divide the lower pulley diameter by the upper pulley diameter. Lets say the crank pulley is 7.50" and the stock supercharger pulley is 3.0". This gives you a pulley ratio of 2.5. Now that we know the pulley ratio we can calculate the actual supercharger speed. Say we spin the engine to 6500 RPM’s. If we take 6500 and multiply it by the pulley ratio (2.50) we end up with 16,250 rotor RPM’s. Now let's take this up a notch. We setup have a 8.25" lower pulley and a 2.45" upper pulley which gives us a ratio of 3.36. So now we take that 3.36 and times it by 6500 and we get 21,887 RPMs. Wow, we really turned it up. This blower is now spinning at almost 22,000 RPMs and this provides a lot of stress/heat on those bearings.

Let's Break it Down

When a supercharger shows up at our shop for porting we have to remember these things. Everything gets taken apart to the absolute bare bones. Every bearing is taken out of the case and/or snout. The case and/or snout is put in the CNC or maybe it's done by hand by your porter. If it spends time in the CNC we get all this milled metal material and a huge amount coolant spray from the CNC during the process. These bearings were never made to resist any type of liquid in the system but now here they are in a CNC or a wash tank subjected to fluids at a high rate or even a high temperature.

Pennywise.. You Know The Rest

Knowing your bearings have gone through this process for which they weren't designed and knowing that you are going to push this supercharger to its newly ported limit - would you even question the thought of doing new bearings? I sure wouldn't and I refuse to put the Synergy name and my name on a ported supercharger without doing this simple and necessary rebuilt step. The time it takes me to tear one down, port it, then assemble it to save $40 - $100 bucks, are we crazy? There is zero labor cost involved since we're already pulling it all apart and putting it all back together. So you've spent the money on a badass port, but you skimp on the essentials? I don't think so. This is where we gotta do better and we have to know better.

So, knowing your newly ported supercharger is being spun at 22,000 to 26,000 RPM makes this simple step a big deal. If you actually look up some of the bearings used from the OEM in their catalog, you will find that the bearings are not even rated for the speed in which you are trying to make them spin, let alone actually last because god forbid your blower have any issues when you ask it to make 950 wheel and more. LOL

So my point is this - take this seriously. I know cost is always a factor, but you know what costs more? Having to do it two or three times when it wasn't right the first time. This will cost you more than you know. And the frustration, can you imagine? Don't get me wrong, I am not perfect either. I am happy to admit there have been times where I have put a new bearing or part into a supercharger and it just failed right from the start. But I'd rather take the low probability of failure route than reusing all the bearings and trying your and my luck.

-

Example product titleExample product title

- Vendor

- Vendor

-

Example product titleExample product title

- Vendor

- Vendor

-

Example product titleExample product title

- Vendor

- Vendor

-

Example product titleExample product title

- Vendor

- Vendor

-

Example product titleExample product title

- Vendor

- Vendor

-

Example product titleExample product title

- Vendor

- Vendor

-

Example product titleExample product title

- Vendor

- Vendor

-

Example product titleExample product title

- Vendor

- Vendor

-

Example product titleExample product title

- Vendor

- Vendor

-

Example product titleExample product title

- Vendor

- Vendor

- Choosing a selection results in a full page refresh.